ATOM

Request a Callback

Leave your details

and we will contact you

Aspiration equipment

Cassette sleeve filter

Cyclones and dust collectors

Filter cabinet

Filter cyclone

Sluice feeder

Spot local filter

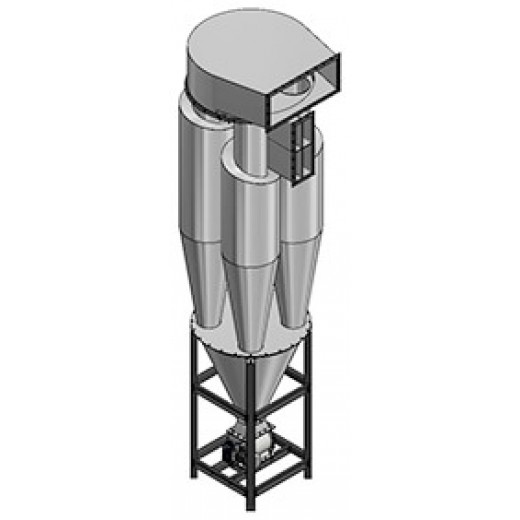

Cyclones and dust collectors

In Stock

Cyclones are installations that are necessary in production, where you need to clean the air from dust and foreign particles. They help to remove various dust particles from the air so that they do not pollute the environment, and also do not enter the human lungs.

Design and principle of operation

The movement of the dust-air mixture is carried out in a spiral, which is due to the design of the unit.

Dusty air enters through the inlet pipe on top of the cyclone-dust collector. Under the influence of centrifugal force,

dust particles are separated, and due to a sufficiently high speed, dust is thrown to the walls of the cyclone.

Then, under the influence of inertia, dust particles fall down, falling into the pyramidal hopper.

After going through several revolutions, the gas-air mixture rises from the bottom of the cyclone, and already purified air comes out of the upper pipe. Technical features * The efficiency of dusty air purification is 70-80%; * No costs for the preparation and supply of compressed air; * Possibility of use for explosive dust; * Possibility of installation both indoors and outdoors; * Long service life due to durable and reliable construction; * Ease and convenience in installation and maintenance; * Application at low initial dust concentrations to ensure standard emissions (no more than 50 mg / m3). As standard, dust collectors are equipped with a body, inlet and outlet pipes. At the request of the customer, the cyclone-dust collector can be equipped with a pedestal, a dust collection hopper, and a snail.

Array